BUYERS GUIDE

What is body armor and why do people use it?

Body armor is used to protect the wearer from injury or death from bullets. Modern body armor is made from a variety of high-tech materials, the most famous being Kevlar®, which is a woven material that is layered to create ballistic panels used in “bulletproof” vests worn by military, civilians, and police around the world. But it’s incredibly important to note:

Materials designed to stop bullets are best described as bullet-resistant against the ammunition it was designed to defeat. But no body armor can guarantee to stop bullets of all velocities, weights, and designs.

With that in mind, certain bullet types can defeat certain types of armor more easily, and some exotic rounds may make a piece of armor much less effective. Armor manufacturing companies have to choose which bullets to prioritize stopping, and while they could potentially develop armor to stop truly exotic rounds, the priority is to protect the user from threats he/she is most likely to face.

Ultimately manufacturers are trying to create the armor that defeats the widest number of rounds, at a reasonable weight, while still being in the realm of affordability…a balance of the “protection, pounds, and price” triangle.

What types of people buy body armor?

All types of people purchase body armor. Law enforcement and security personnel, armored car company employees, bodyguards, and citizens working or living in higher-risk areas. Really, anyone wanting extra protection in the event they are shot at.

How does it work?

Body armor is designed to stop bullets from penetrating the armor, but how it does that depends on the material, which absorbs the bullet’s impact. The bullet is either caught (as with soft armor), disintegrated (as with steel and, to a lesser extent, ceramic armor plates), or captured within the armor (as with polyethylene armor plates).

Though body armor protects the wearer from the most devastating part of a bullet’s impact, the possibility of injury via the blunt impact of the bullet due to what is known as backface deformation still remains. Current specifications allow for up to 44mm of backface deformation (1.73”).

Energy Transfer

When a bullet hits armor of any kind, it carries energy. Heavier and faster bullets transfer more energy and that energy has to go somewhere. Different types of armor deal with that energy in different ways.

Soft armor

is designed to ‘catch’ the bullet to stop it, which takes time and distance. As the vest stops the bullet, the vest is deformed in the direction of the projectile’s travel toward the wearer’s body. The distance the armor deforms is commonly called “backface deformation.” The amount of backface deformation depends on the protective level of the vest and how much energy the bullet has.

Hard armor

is affected by the bullet's energy transfer as well, but in different ways: steel armor shatters projectiles and redirects the pieces, while polyethylene and ceramic plates absorb the bullet and its energy.

All types of armor can experience backface deformation, with soft armor and UHMWPE (sometimes referred to as poly, polyethylene, PE, or HDPE plates) experiencing the most deformation.

Backface deformation often results in bruises, broken bones, contusions, and other injuries, sometimes referred to as blunt force trauma. Depending on the armor type, the round used, and the location of the shot, the wearer can still suffer a serious or fatal injury.

What is body armor made of?

There are two types of body armor, soft and hard.

Soft armor is designed to stop lower velocity ammunition and is used in “bulletproof” vests (though remember that no armor is truly bulletproof). The most commonly used materials use to make soft armor are:

P-Aramid material (such as DuPont Kevlar®, Teijin Twaron®),

Ultra High Molecular Weight Polyethylene material (such DSM’s Dyneema® or Honeywell Spectra®)

A combination of the two

These materials are then formed into a fabric that is cut and sewn to create the armor panels used in ballistic vests. Soft armor offers lightweight, flexible, and concealable protection against most handgun ammunition.

What are the Pros vs Cons of soft armor?

Pros

Thin

Flexible

Lightweight

Concealable

Cons

Stops most pistol & shotgun rounds

Not stab resistant

High backface deformation, even though it stops the bullet

More expensive when getting into the super lightweight and exotic hybrid materials

Susceptible to heat and sweat/salts, so must be cleaned regularly

Hard armor is designed to protect the user from rifle-rated threats. As a byproduct of this, it also protects against handguns and shotgun ammunition. The most commonly used materials use to make hard armor are:

Armor-Grade Steel (such as AR500, AR550, and AR600) and steel alloy armor blends

Ultra-High Molecular Weight Polyethylene (UHMWPE, also called polyethylene or PE plates)

Ceramic Composites (such as aluminum oxide, boron carbide, or silica carbide)

A combination of these materials (such as ceramic paired with UHMWPE)

What are the Pros and Cons of hard armor?

The pros and cons of hard armor vary as much as the different materials used to make it.

Steel Armor

Pros

Edge-to-edge protection

Stops M855 'green tip' and similar

Affordable

Can last for years

Minimal backface deformation

Usually thinner than comparable PE and ceramic plates

Multi-hit capable

Cons

Heavy

Bare steel prone to bullet fragmentation

Ineffective against armor-piercing ammo

UHMWPE

Pros

Lightweight

Buoyant

Stops M193 and similar high-velocity ammunition

Multi-hit capable

Cons

More expensive

Thick

Can lose integrity if exposed to high heat for too long

Ineffective against “green tip”, armor-piercing, or similar ammunition

NIJ testing protocol allows for up to 2” edge failure

Ceramic

Pros

Effective against the most powerful rounds

Thin

Less expensive than PE

Can be multi-hit capable

Lighter than steel

Cons

More expensive than steel

Prone to cracks or breaks if not stored correctly, reducing protection. Should be annually inspected/X-rayed

NIJ testing protocol allows for up to 2” edge failure

Level IV test protocol only requires it to stop 1 round

Heavier than UHMWPE

What is the difference between “In Conjunction With” and stand-alone armor plates?

An in-conjunction-with (ICW) plate is designed to be used with some sort of backing material, usually a Level IIIA soft armor ballistic vest or “plate backer” (a plate-sized piece of soft armor) which helps to absorb the kinetic energy and catch potential spall on the backside. Some ICW plates may be rated for Level III threats (six rounds of 7.62x51 ball ammo) when used in a stand-alone fashion, and Level IV (one round of .30-06 M2AP ammo) when used with a backer or Level IIIA vest. It is important to note ICW plates are Certified with a particular soft armor vest so while they can be used with all soft armor vests they may not meet the proper testing standard to stop the rifle bullets. Always buy an ICW plate certified with the soft armor.

In comparison, stand-alone plates are capable of stopping their NIJ rating without the use of any backing materials. This offers more flexibility in that you can use them in a smaller plate carrier (vs. a carrier for a larger vest) as well as save some weight from not needing the backing vest or panels.

What is the difference between a carrier and vest?

A ballistic vest usually refers to the soft armor panels that are designed to stop the projectile. These panels are then placed into a carrier that holds the armor and is designed to be worn by the user.

Hard armor plates are worn in a plate carrier, though there are some carriers that are designed to hold both soft and hard armor plates, such as our Freedom concealable and All Star tactical products.

The term “bullet proof vest” or “ballistic vest” refers to the combination of armor and carrier, and usually refers to a soft-armor based system.

What is Slash and Spike protection, and is it the same as ballistic armor?

Slash and spike protective armor is designed to stop knives, box cutters, ice picks and other edged or puncture weapons.

The NIJ has issued NIJ 0115.00, which is the standards document used to create levels and testing standards for spike and stab resistance.

Similar to ballistic ratings, there are three rating levels for NIJ 0115.00, each increasing its level of protection. Level 1 protection is best suited for concealable vests, whereas Levels 2 and 3 are for overt body armor as might be worn by police, military, or correctional officers.

According to the NIJ spike standard, the maximum blade or spike penetration allowable for the E1 test is 7 mm (0.28 in), with a 50% increase in energy for the E2 overtest condition. The maximum blade or spike penetration of 20 mm (0.79 in) is allowable for the E2 test. This overtest is required to ensure that there is an adequate margin of safety in the armor design.

The NIJ document has details on the standards and testing procedures, and we highly recommend downloading and reviewing it to gain a better understanding of this type of armor.

As to the question of if it’s the same as ballistic armor, SPIKE ARMOR OFFER NO BALLISTIC PROTECTION, and ballistic soft armor offers no protection against stab/spike threats, and only minimal protection against some slash weapons.

What is backpack armor? How does it work?

Backpack armor most often consists of soft armor panels that are designed to fit into a backpack, often in a computer sleeve or similar pocket in the backpack.

Sizes can range from 10”x12” to 11”x14” depending on the seller.

Once in the backpack, the soft armor works as it would in a ballistic vest.

The backpack can protect the back when worn normally or can be turned around and worn on the front if coverage is desired there.

Why does body armor have a lifespan/expiration date?

Body armor doesn’t have an expiration date, but it does have a warranty period.

How long a vest will last is determined by what it’s made of, how well it’s cared for, and how much abuse it’s suffered during its “lifetime.” The biggest factors in determining how long a vest lasts (versus the warranty period) are wear-and-tear, sweat, humidity, water, and heat.

The NIJ therefore mandates that certified armor must have a five-year warranty. This testing simulates the bending, folding, sweating, heating, cooling, and other abuse that armor will encounter over its useful life. This is why armor companies offer set-period warranties.

What are the protection levels? Why is body armor “certified”?

What is the NIJ?

The National Institute of Justice is the research arm of the U.S. Department of Justice. It is “dedicated to improving knowledge and understanding of crime and justice issues through science,” according to their website.

One of the areas that the NIJ covers is the oversight of performance standards for body armor, including testing of armor against their standards to ensure compliance and sponsoring research to help advance the performance of body armor materials and design.

Why is our armor NIJ certified?

The NIJ has created minimum performance standards against which our and many other brands of armor are tested against to help assure purchasers that the armor meets the levels of performance the NIJ has set forth in the 0101.06 body armor standards.

Protection levels, explained

There are currently 5 levels of body armor protection, from Type IIA (least protective) to Type IV (most protective). Sometimes you’ll see the classifications referred to as “Level IIA”, etc., but for all practical purposes, they mean the same thing.

For detailed specifications, including testing specs for “conditioned armor”, 0101.06 body armor standards, where the listing starts on Page 3 of the document. Details on protection levels starts on Page 3 and the protocol for conditioning armor (to simulate armor being worn over time) starts on Page 27. The following lists specs on new armor only.

Soft Armor

Type IIA (9 mm; .40 S&W)

- 9 mm Full Metal Jacketed, 124gr Full Metal Jacket Round Nose (FMJ RN) @1225 FPS

- 40 S&W 180gr FMJ @1155 FPS

Type II (9 mm; .357 Magnum)

- 9 mm 124gr FMJ RN @1305 FPS

- .357 Magnum 158gr Jacketed Soft Point (JSP) @1430 FPS

Type IIIA (.357 SIG; .44 Magnum)

- .357 SIG 125gr FMJ Flat Nose (FN) @1470 FPS

- .44 Magnum 240gr Semi Jacketed Hollow Point (SJHP) @1430 FPS

Hard Armor

Type III (Rifles)

- 7.62x51 mm 147gr FMJ, steel jacketed bullets (U.S. Military designation M80) @2780 FPS

Type IV (Armor Piercing Rifle)

- .30-06 caliber 166gr armor piercing (AP) bullets (U.S. Military designation M2 AP) @2880 FPS

What is the difference between your Light, Lighter, and Lightest armor?

Choosing body armor is a juggle between protection, price, and pounds (weight). The lighter and more protective you go, the more expensive armor tends to become as more advanced and exotic materials are introduced into the final product.

Light

Light is most popular among citizens looking for Level IIIA+ protection that is relatively lightweight yet affordable

Lighter

Lighter falls between these two, costing less than the Lightest but weighing more than the Light

Lightest

Lightest is popular among LE, security, and other professionals looking for the lightest, thinnest, most concealable, and most flexible IIIA+ protection we offer, but it costs more

How do I determine what size vest I should get?

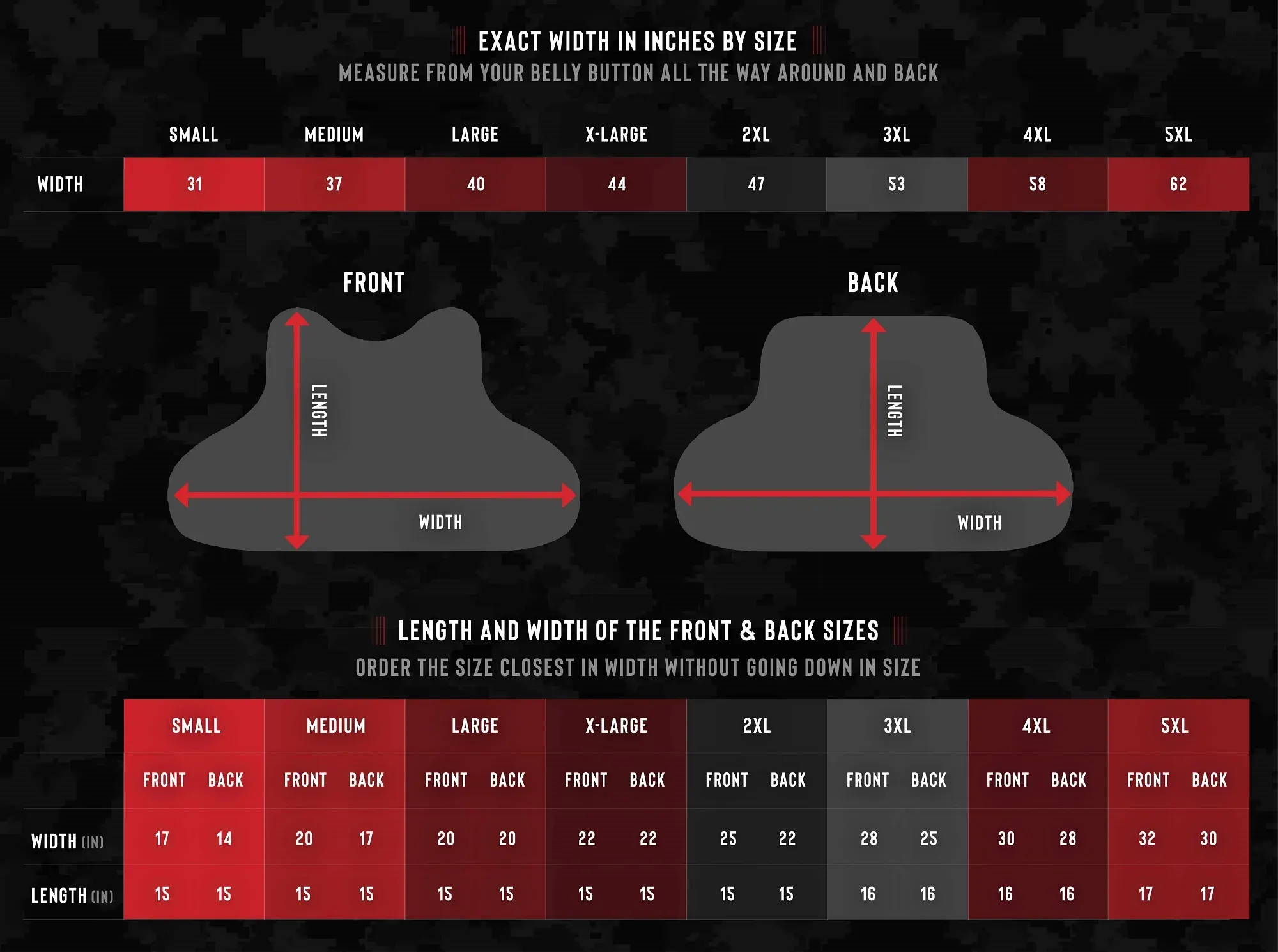

We recommend measuring around the widest part of your upper body. Once you have this measurement align it to the closest size below in the chart. If you select a size smaller than your measurement you will have a gap on the sides of our traditional wrap armor and if you purchase a size up you will have overlap which is more ideal. To determine your overlap divide the difference from your measurement to the size selected by two.

How do I take care of my body armor?

Properly caring for your body armor will help ensure that your investment lasts as long as it can. Abusing armor by letting it get dirty, creasing it (soft armor), storing it wet, handling it roughly (ceramic) can shorten your armor’s lifespan.

Care and Maintenance

a. Soft armor

Store soft body armor in a cool, dry place, and out of direct sunlight.

Avoid folding or creasing soft armor, as it can damage the fibers and materials making up your protective panels

Regularly inspect your armor for signs of wear, such as holes, fraying, or mold. Contact your armor vendor for guidance if you notice damage.

Clean your soft armor using a damp cloth or sponge to wipe the panels’ outer shell (removed from the carrier). Avoid using cleaners or solvents that could damage your armor.

Replace your soft armor as needed, since armor has a warranty lifespan. Your manufacturer can offer better guidance based on the materials, how you stored it, and the amount of use it’s experienced

b. Hard armor

Ceramic

Ultra-High Molecular Weight Polyethylene (UHMWPE)

Steel

Carriers

Purchasing Armor

d. Ordering, Shipping, Returns

Ordering

Shipping

We offer FREE UPS Ground Shipping with Tracking on all orders over $200.

Orders under $200 we charge $14.95 for UPS Ground Shipping with Tracking.

Most orders ship from our warehouse in sunny Boca Raton, Florida.

Orders to Alaska, Hawaii, and Puerto Rico do not require additional shipping charges but they may have longer delivery times, and orders to Canada are charged an actual shipping/taxes/duties rate and are sent via UPS Ground with Tracking.

National Body Armor is not responsible for any delays in shipping caused by factors beyond their control, such as weather or carrier issues.

Customers can track their order using the tracking number provided in the shipping confirmation email. We will also send you an email when it is out for delivery, has been delivered, and for a final review of the product a few days later.

National Body Armor may require a signature upon delivery for certain orders to ensure proper receipt of the items.

Customers should inspect their order upon receipt and contact National Body Armor immediately if there are any issues or discrepancies with the order.

Returns

National Body Armor wants you to be happy with your purchase, we offer a 10-day Fit Guarantee. If you’re not satisfied with your purchase within 10 days of receiving the product, you may obtain a Return Merchandise Authorization (RMA) from our Returns Portal. Once the exchange is approved we will email you an authorization and provide you direction for sending it back to us at your expense. We recommend sending it back to us in the original packaging and via UPS. All items returned must be in a new unworn condition.

If there’s a defect in the product or an error in fulfillment, send us a picture of the issue via our Returns Portal within 10 days, and we’ll send you a shipping label and replace the item or issue a store credit for the value.

Canadian orders, please review our Canadian Shipping Terms and Conditions

Purchases on a dealer/wholesaler account do allow for returns, refunds, or exchanges, so be certain of the items and quantities you’re ordering.

Warranty - National Body Armor offers the following limited warranty

Nylon panel covers against any defects in workmanship or materials for twenty-four (24) months after the date of purchase.

2-year limited warranty on the carrier

5-year limited warranty on the soft armor

10-year limited warranty on hard armor

National Body Armor warrants that for a period of (5) years from the date of purchase, the panels will conform to the minimum requirements of the NIJ protocol for ballistic intervention during an actual confrontation at the stated threat level (if your ballistic panels are not labeled in compliance with NIJ requirements, then this warranty does not apply to your panels).

This Warranty Is Subject To, And Expressly Conditioned Upon, Strict Compliance With The Following Conditions:

- The panel must not be torn, damaged, or altered in any way

- The panel must not be subjected to abuse or misuse during service

- The panel may only be used or placed in a cover or carrier it is designed or intended for

- The panel must not be permitted to be excessively wet

- The panel must not be subjected to excessive heat

- The panel must be properly stored (i.e., not in excessively hot or damp conditions)

Is body armor legal?

As body armor is often associated with firearms, it's common to have questions about regulations on the purchase or ownership of body armor.

It is legal under federal law and in 49 of the 50 states for law-abiding, non-felon citizens to purchase, own, and use body armor for lawful purposes. Using body armor during the commission of a crime can add penalty enhancements.

No license is needed to purchase or own body armor, but there are two states in which citizen purchase (Connecticut) or ownership (New York) are restricted.

Connecticut

Body armor cannot be purchased in the state of New York unless you work within a profession approved for ownership of body armor such as law enforcement.

New York

It is legal for citizens to purchase and own body armor, but does restrict its purchase and sale, which must be done through face-to-face sales. Online retailers cannot, by law, market to or sell body armor to Connecticut residents, with the exception of authorized officials or sworn officers of law enforcement or corrections agencies, or members of the U.S. military or National Guard. (CGS § 53-341b). Violating this law is a Class B misdemeanor. If you are military or LE in Connecticut, please contact us for instruction on how to order.

Minors

We do not sell to minors. You must be 18 to buy our products.

Outside the US

We are registered with the US Department of State and can export worldwide with the proper export licenses. Our Defense Trade Controls Compliance Registration Code is M44107. We comply with all International Trade and Arms Regulations (ITAR) and the Foreign Corrupt Practices Act (FCPA).